Is 3-D Printing Misleading Entrepreneurs?

Open your browser. Type “Prototype Manufacturing” into the search bar. Hit return, then ignore the results and look to the right where most browsers place sponsored (or paid advertisements). I see a lot of exclamation points.

Open your browser. Type “Prototype Manufacturing” into the search bar. Hit return, then ignore the results and look to the right where most browsers place sponsored (or paid advertisements). I see a lot of exclamation points.

Fast Turnaround!

Low Prices!

Free Quotes!

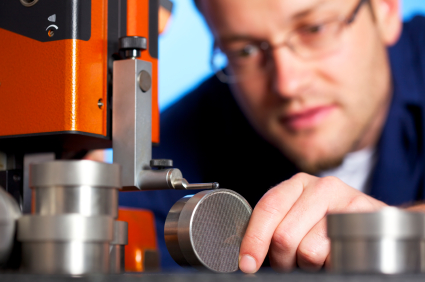

Advances in 3-D printing technology is making creating simple prototypes a cost-effective option for many entrepreneurs and manufacturers exploring new products, but is it the right choice? Fast, free or low-cost prototypes don’t reflect all aspects of a final product.

The companies in those ads displayed on your search engine typically use small 3-D printers that fit on a large table. They cannot produce large components cost-effectively – yet. There are 3-D printers able to create larger components, but they are currently more expensive and take a long time to produce.

3-D printed components are built in layers. Most 3-D printers rely on plastics which are easy to melt and mold into the required piece. Plastics can reflect the shape and size, but aren’t reliable for testing, especially under high temperature conditions. Metals can be used in 3-D printing, as well as glass and other specialized materials, but those printers once again are more expensive.

3-D printers don’t yet have the same precision as a manufactured part. The accuracy in production varies by printer, but typically ranges from +/- 0.1mm, a small number with a margin for error that can be critical to a product.

While an engineer might understand these and other limitations of a 3-D printer, a guy or gal with a great idea may be misled and believe a 3-D printed prototype is a fully working and scaled visualization of his or her product. What are your thoughts on 3-D printing’s role as a tool for helping entrepreneurs design for manufacturability?