3D Printer to Construct Steel Foot Bridge in Amsterdam

MX3D, a Dutch research and development organization, is working in partnership with several companies including Autodesk, and Lenovo, to make their ambitious 3D printing project a reality. The combined talents of these firms will attempt to construct a pedestrian bridge across a canal in Amsterdam using 3D printing technology.

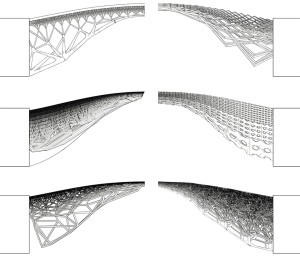

The engineers at MX3D have worked to create robotic printers that will be capable of executing the job autonomously. The robotic printers’ six-axis arms have welders on each tip that will essentially “draw” the steel structure from each side of the canal. 3D robotic printers use various types of metals, such as aluminum, bronze, copper, or steel for construction. The printers create the structures in the air without the need of traditional support structures, such as scaffolding because the builds are sequential and can be constructed in any direction.

The MX3D printing technology will differ from current 3D printing technologies in the sense that it prints “outside the box.” Currently, 3D printed objects are limited by the size of the printing space. Large objects are printed piece by piece and assembled later. By utilizing this new six-axis robotic approach, neither design nor function will be hampered or confined to a square box. The robotic application will take 3D printing to a whole new level of design, and the potential for the MX3D application is limitless as it enables 3D printers to produce practical, life-size constructs.

Engineers expect that construction will begin by 2017. There were a some growing pains during the developmental stage of the printers. MX3D engineers have dealt with the printers generating “worm-like” globs, welding machine explosions, clogged nozzles, and the robot got disoriented. Multiple testing sessions finally produced an operational robotic printer that was able to create the structures.

The bridge structure is designed by Autodesk project engineers and will employ a proprietary software program. It will synchronize with the technical development of the bridge, giving due consideration to the bridge’s location. The completed bridge will be 24 feet in length, made of a steel composite created at the University of Delft, and will have a superior tensile strength. It will also be functional and is expected to handle normal foot traffic.

MX3D envisions a time in the not too distant future when advances in future technology will foster the development of robotic concrete printers too, in the hopes that the 3D printing of significant structures such as buildings will be possible.